About the Department

Profile

SSM College of Engineering, established in 1998, offers specialized undergraduate (B.Tech) and postgraduate (M.Tech) programs in Textile Chemistry, with a strong emphasis on textile coloration and chemical processing rather than traditional chemistry. This makes the course more accessible to students who are primarily interested in textile technology and its chemical applications, as it focuses on dyeing, printing, finishing, and fabric treatments that directly enhance the properties of textiles like color fastness, texture, and aesthetic appeal.

Additionally, the college assures 100% placement assistance, with opportunities across multiple companies in the textile industry. A significant strength of the program lies in the highly qualified and dedicated faculty of the Textile Chemistry department. Students also benefit from several industrial visits, providing real-world exposure and a deeper understanding of textile manufacturing processes. The college organizes guest lectures, seminars, and workshops, giving students the opportunity to interact with industry experts and stay updated on the latest developments in textile chemistry. Internships with leading textile companies further enhance their practical knowledge and employability. Since 2002, the institution has secured more than 20 gold medals, reflecting its academic excellence and commitment to producing top-tier graduates.

Vision

To become a centre of excellence in textile wet processing by imparting technical, managerial, R & D and entrepreneurship activities through quality education.

Mission

PROGRAM EDUCATIONAL OBJECTIVES (PEOs)

To enable the graduate students of Textile Technology and allied studies to

PROGRAM OUTCOMES (POs)

Upon completion of the program, the student shall be able to

PROGRAM SPECIFIC OUTCOMES (PSOs):

By the completion of Textile Chemistry program, the student will have following program specific Outcomes.

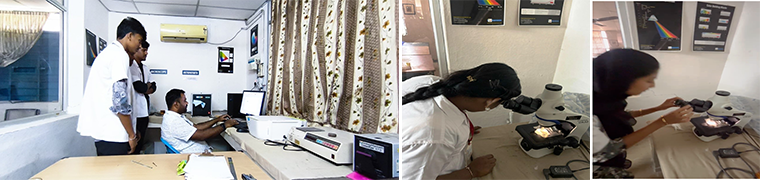

Lab Facilities

FIBRE SCIENCE LABORATORY

A Fiber Science Laboratory is a specialized research facility focused on studying the properties, behaviours, and applications of different types of fibers. Fiber science is an interdisciplinary field that combines aspects of materials science, chemistry, biology, engineering, and physics. The laboratory investigates both natural fibers (such as cotton, wool, and flax) and synthetic fibers (such as polyester, nylon, and carbon fibers), exploring their physical, mechanical, and chemical properties in order to improve their performance, processing, and applications across various industries.

TEXTILE YARN AND FABRIC MANUFACTURING LABORATORY

A Textile Yarn and Fabric Laboratory is a specialized research and testing facility where various aspects of yarn production, fabric construction, and textile properties are studied, tested, and optimized. The laboratory focuses on understanding the characteristics, performance, and quality of yarns and fabrics, which are essential for various industries, including apparel, home textiles, technical textiles, and more. The lab plays a key role in the development and innovation of new textile products, processes, and technologies.

TEXTILE CHEMICAL ANALYSIS LABORATORY

A Textile Chemical Analysis Laboratory is a specialized facility dedicated to the analysis of the chemical composition, properties, and behaviour of textiles and their components. This laboratory plays a crucial role in the textile industry by providing insights into the materials used in fabric production, dyeing, finishing, and the overall quality and safety of textiles. It helps ensure that textiles meet industry standards, comply with regulations, and perform as expected in their intended applications.

DYEING LABORATORY

A Dyeing Laboratory is a specialized facility where the process of dyeing textiles is studied, tested, and optimized. Dyeing is the process of applying colour to fibers, yarns, or fabrics, and the laboratory is dedicated to researching different techniques and chemicals to achieve consistent, high-quality, and sustainable results. It plays a key role in the textile and fashion industries by ensuring that colours are applied evenly and fast, and that the fabric retains its quality after repeated use or washing.

PRINTING LABORATORY

A Printing Laboratory is a specialized facility where the process of textile printing is studied, tested, and perfected. Textile printing is the technique of applying designs, patterns, or images onto fabrics, usually by using dyes, pigments, or inks. The laboratory focuses on experimenting with different printing techniques, colour applications, and materials to create consistent, high-quality prints on textiles. This lab is essential for research and development in the textile, fashion, and home décor industries.

FINISHING LABORATORY

A Finishing Laboratory is a specialized research and testing facility that focuses on the various finishing processes applied to fabrics or fibers to improve their appearance, feel, and performance. These processes can include treatments to enhance the fabric's texture, colour, durability, water resistance, flame retardancy, and other functional properties.

TEXTILE TESTING LABORATORY

A Textile Testing Laboratory is a specialized facility dedicated to testing and evaluating the physical, mechanical, chemical, and functional properties of textiles. This laboratory plays an essential role in the textile industry by ensuring that fabrics and finished products meet industry standards, quality control requirements, and safety regulations. The results of these tests help manufacturers assess the quality, durability, comfort, and overall performance of textile products, ranging from clothing and home textiles to industrial fabrics.

GARMENT LABORATORY

Garment laboratory is a facility where the techniques, methods, and processes involved in the creation and assembly of garments are studied, tested, and refined. This lab focuses on various aspects of garment production, from pattern making and fabric selection to sewing techniques and finishing details. It plays a key role in ensuring that garments are constructed efficiently, with attention to quality, durability, comfort, and style.

LIST OF THE MAJOR EQUIPMENT

| S.No | Equipment |

| 1 | Computer Color Matching Machine |

| 2 | Soft Flow Dyeing Machine |

| 3 | Electron Micro Scope |

| 4 | Open Bath Beaker Dyeing Machine |

| 5 | Pneumatic Padding Mangle |

| 6 | Dry Cleaning Machine |

| 7 | Garment Dyeing Machine |

| 8 | Garment Washing Machine |

| 9 | Tumble Drying Machine |

| 10 | Infra Red Dyeing Machine |

LIST OF MACHINERIES AND LAB EQUIPMENTS

| S.No | NAME OF THE EQUIPMENTS |

| 1 | COMPUTER COLOUR MATCHING SYSTEM |

| 2 | DRYING,CURING AND HEAT SETTING CHAMBER |

| 3 | STEAMER |

| 4 | MINI KIER |

| 5 | MINI WINCH |

| 6 | MINI JIGGER |

| 7 | MINI PADDING MANGLE |

| 8 | GLYCERIN BATH BEAKER DYEING MACHINE |

| 9 | HOT AIR OVEN |

| 10 | ELECTRONIC WEIGHING SCALE |

| 11 | PRINTING TABLE |

| 12 | VACUUM PUMP |

| 13 | WATER BATH |

| 14 | HIGH SPEED STIRRER |

| 15 | PRINTING SCREENS |

| 16 | PRINTING SCRAPER |

| 17 | STIRRER |

| 18 | PRINTING TABLE |

| 19 | CROCKMETER |

| 20 | POCKET PH METER |

| 21 | PERSPIROMETER |

| 22 | DIGITAL LIGHT FASTNESS TESTER |

| 23 | FABRIC DYEING MACHINE(SOFT FLOW) |

| 24 | PADDING MANGLE (PNEUMATIC) |

| 25 | OPEN BATH BEAKER DYEING MACHINE |

| 26 | INFRA COLOUR DYEING MACHINE |

| 27 | GREY SCALE FOR STAINING |

| 28 | GRAY SCALE FOR CHANGE IN COLOUR |

| S.No | NAME OF THE EQUIPMENTS |

| 29 | WASH FASTNESS TESTER |

| 30 | COLOUR MATCHING CABINET |

| 31 | TDS METER |

| 32 | WASHER EXTRACTOR |

| 33 | WASHER EXTRACTOR |

| 34 | DRY CLEANING MACHINE |

| 35 | VACUUM IRONING TABLE |

| 36 | BOILER MACHINE |

| 37 | GARMENT WASHING MACHINE |

| 38 | IRON BOX |

| 39 | VISCOMETER |

| 40 | SOXHLET EXRACTER |

| 41 | GLASS EQUIPMENTS |

| 42 | PLASTIC EQUIPMENTS |

| 43 | STOP WATCH |

| 44 | BURATE STAND |

| 45 | SEWING MACHINE |

| 46 | MICROSCOPE |

| 47 | CODITIONING CHAMBER |

| 48 | SOXHLET APPARATUS |

| 49 | SPECTROPHOTOMETER |

| 50 | THERMOMETER |

| 51 | STAINLESS VATS |

| 52 | INCUBATOR |

| 53 | HAND DRYER |

| 54 | HTHP DYEING MACHINE |

| 55 | GARMENT DYEING MACHINE |

Renowned Alumni

Batch : 1998 - 2002

Organization : KVIC Government of India, Director

Batch : 2000 - 2004

Organization : Madura Coats India P Ltd, Colour System Manager

Batch : 2003 -2007

Organization : Enrerprise Data Governance. USA Capital one, Senior Manager

Batch : 2005 - 2009

Organization : Mirjan Rouden LTD, London Design Engineer

Batch : 2008 -2012

IIT - Delhi, Professor

Value Added Programs

Workshops / Conferences / Seminars / Symposium

Guest Lecturers

Department of textile Chemistry conducts programs like

In addition to this we encourage the students to make periodical industrial visit to improve practical exposure in the industry

Faculty Attended Seminars And Workshops

| S.No | Name of the students | Events |

| 01 | Mr. M. Krishnakumar | Latest trends & Problems and Remedies in PET,P/C and P/W Blends dyeing |

| 02 | Mr.Sathish.N.M:Colour Tex | Colour fastness Testing |

| 03 | Prof.Dr.Ruma Chakrabarti | Computer Colour Matching |

| 04 | K.S.Madheswaran | Silicone & its Chemistry |

| 05 | Mr.Vignesh Amalraj | Human Ecology |

| 06 | Mr.Vengatesh | Advanced wet Processing |

| 07 | Mr.Ravi Kishore | Placement opportunities in Garment Industries |

| 08 | Dr.Tamilisai | Opportunities for higher studies in CMU-USA |

| 09 | Mr.T.Boopathy | Modern Textile Finishing |

| 10 | Mr.Jayaprakash Gandhi | Placement |

| 11 | Mr.M.Muthumanikam | Silicone & Emulsions |

| 12 | Dr.John T Smith | Textile Institute |

| 13 | Ms.Carol Watkinson | Fabric Unravel |

| 14 | Dr.V.Subramaniam | Modification of Polyeaster fibre |

| 15 | Mr.Luc Lorthioir | Export Opportunities for european market |

| 16 | Mr.S.Vivekanandhan | Developments in Auxiliaries |

| 17 | S.Arunagiri | Recent trends in Machineries |

| 18 | Mr.Parthiban | Placement opportunities |

| 19 | Mr.R.Vallarasu | Cheese dyeing Machine |

| 20 | Mr.T.Boopathi | Recent trends in finish |

Industrial Visits & In-plant Training

| S.No | Name of the Company |

| 1 | SRG Apparels - Nethji Apparel Park - Perumanallur |

| 2 | Keetex – Cochin |

| 3 | WF-Bird - Kerala |

| 4 | Motherland - Karnataka |

| 5 | ITS - Tirupur |

| 6 | Saranya Spinners - Thuraiyur |

| 7 | Pallava Spinners - Veppadai |

| 8 | SRG Processing - Tirupur |

| 9 | Jasmine Towels - Madurai |

| 10 | Naveena Printers - Chitode |

| 11 | Jaishree Processors - Gangapuram |

| 12 | JJ Processors - SIPCOT Perundurai |

| 13 | WF Bird - Perundurai |

| 14 | Indian Stitches - SIPCOT Perundurai |

MoU with Companies

MoU's

© 2025 | SSM College of Engineering, All Rights Reserved.